Improving Greenhouse Crop Yields with AI

July 29, 2021Between frequent climate extremes and the rising human population rising, major breadbasket nations are struggling to satisfy supply and demand. A new Israeli ag-tech company is providing artificial intelligence to improve local agriculture.

The more intense climate change grows, the harder it becomes to alleviate the many stresses it puts on our society. Agriculture is one such aspect of society feeling the burn, and it’s only getting worse as the world population continues to grow alongside consumer demand. Not only is agricultural output around the world suffering, especially in major breadbasket nations, but now it is struggling to maintain production capacities capable of satisfying larger international consumer bases.

60% of the world’s food production originates from just five countries: the United States, China, Brazil, India, and Argentina. The presence of climate change, however, has effectively increased the frequency of drought periods in some of these regions, harming crop harvest in the process. Studies even show that 39% of American crop failures are linked to the impaired state of soils and climate. Although changes in temperature affect each crop differently, rice, corn, and soy–three of the four most globally consumed grains–are known to experience the most severe impacts.

According to a 2020 case study by the McKinsey Global Institute, the likelihood of widespread breadbasket shortages will significantly increase over the next three decades. Based on climate models, the researchers estimate an 18% chance of multiple breadbasket failure by 2030 and 34% by 2050. But due to competitive disadvantages, many smaller and developing countries tend to import grain from major breadbasket nations because it is cheaper than producing domestically. However, in light of the growing probability of widespread crop failures and shortages, this could prove quite detrimental for Israel because the country imports 90% of its grain and legumes and only has five weeks worth of emergency stocks to fall back on.

So, if Israel’s reliance on breadbasket nations is so risky, what about its own local agriculture? Despite the country’s well-refined water irrigation capabilities, unfortunately its climatic conditions are still very unforgiving, especially when it comes to long drought periods. Israel’s annual rainfall has decreased by 9% since 1993, and it has already experienced a notoriously long drought from 2003 to 2010. The near future does not look particularly promising either as Israel’s average annual temperatures are projected to rise between 0.3°C and 0.5°C every ten years alongside a 20% decrease in precipitation by 2050.

Currently exceeding 9.2 million, Israel’s Central Bureau of Statistics expects the country’s population to reach 10 million by the end of 2024 and projects there will be 15 million by the end of 2048. With these growing figures, it is becoming more and more uncertain whether conventional agriculture is going to cut it, which has prompted the need to integrate sustainable solutions into food production. Currently, there are over 440 active companies operating in Israel’s Ag-Tech industry, and 172 of them were founded within the last seven years, investing the majority of efforts towards improving plant and livestock sciences and innovating sensors and digital agriculture.

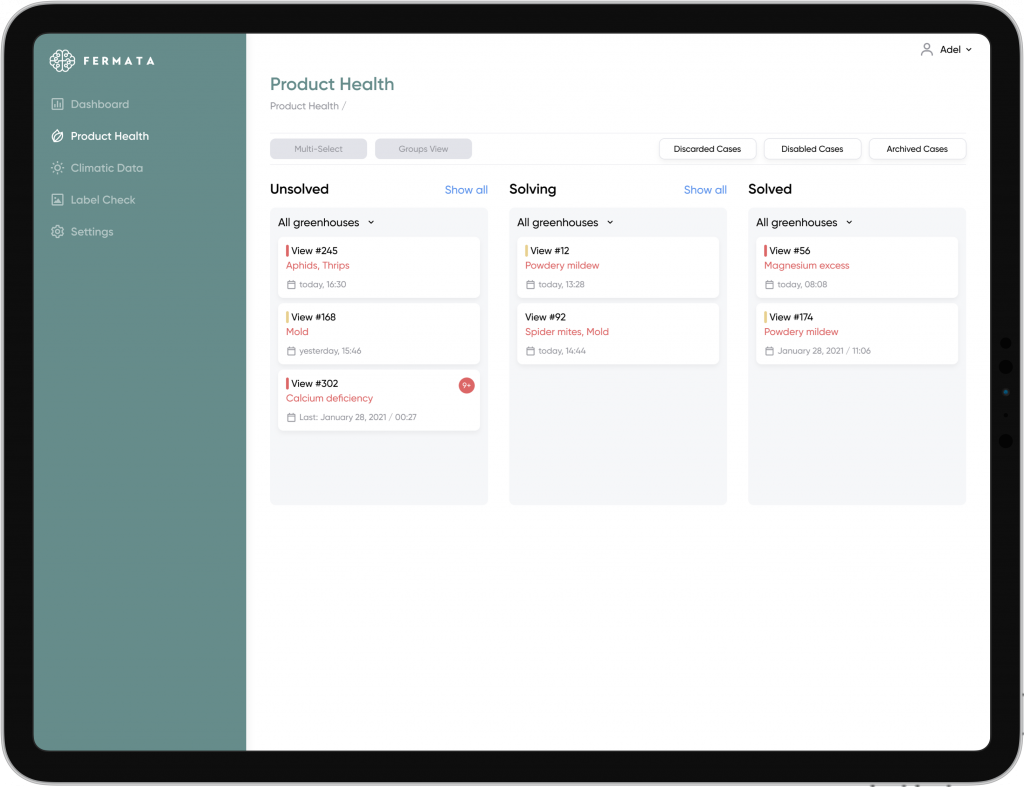

An Artificially Intelligent Solution

Considering that an average of one in every eight crops around the world fail to yield due to fungal disease, a company called Fermata.Tech has developed a successful solution for greenhouses involving artificial intelligence (AI) to facilitate plant growth by identifying diseases and detecting the presence of pest activity much earlier.

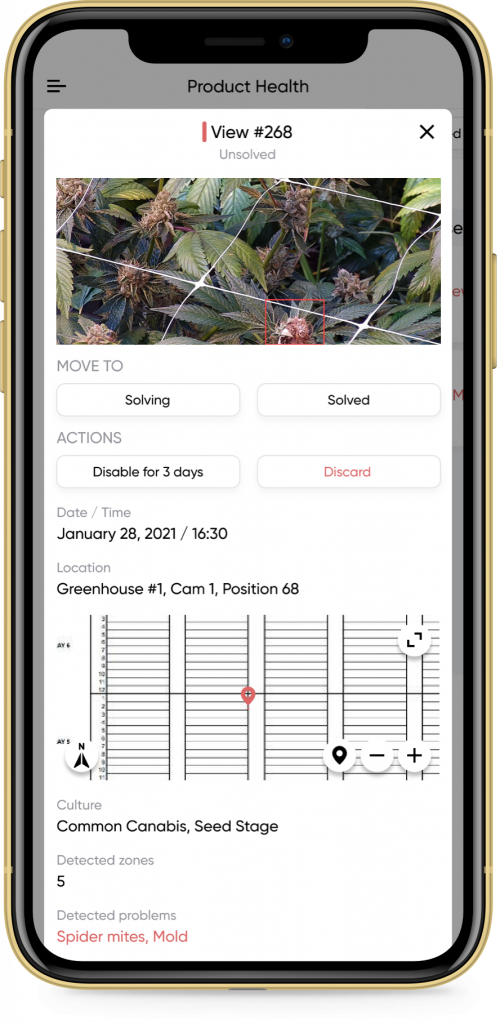

“To achieve this goal, we install special cameras in greenhouses that observe and take pictures of every single plant,” says Fermata.Tech CEO, Valeria Kogan. “Then the AI analyses the images and identifies what’s really going on like whether the plants are healthy or unhealthy, which diseases or pests might be present, or the rate at which the plants are growing–whatever the farmer needs.”

So far, their methods have enabled greenhouses to cut disease-related harvest loss by 30-40% and reduce active human monitoring by 50%, according to the company’s trials.

Photo courtesy of Valeria Kogan.

“Workers tend to only notice when a plant is infected once the disease has already spread, which is where a lot of production is lost, making it one of the main sources of food waste on the planet,” says Kogan. “Up to 40% of greenhouse and open field crops are lost due to disease, and this generates an annual financial loss of 7 billion dollars.”

Because the workers who visually monitor plants growing inside greenhouses are not trained agronomists, they need to contact an agronomist to determine how best to proceed with the affected plants if they see something questionable among them.

“On average, agronomists come and inspect plants once a week, but this takes up a lot of time, especially when these greenhouses host upwards of 10,000 plants,” says Kogan. “Obviously, human vision is limited. It’s like a jungle! So, it’s just not realistic to monitor every leaf of every plant every day like that. Artificial intelligence replaces this process and makes it automatic.”

To develop their AI system, Fermata paired with a team of agronomists to create an extensive database of high-quality plant images each accompanied by images of what they look like when afflicted by certain diseases or pests. When the image sensor technology detects a crop, it is automatically matched against this programmed data and analyzed for its health status.

“Our core expertise is in software development, and we developed this AI solution to make it possible to analyze images and then define what’s going on with the plants in these images,” says Kogan.

This information is then transferred to Fermata where the company then decides how to proceed. Because their AI can detect a very wide range of issues from infectious diseases to even noticing if a plant is suffering from dryness, Fermata must be very client oriented because some clients are not fully equipped to deal with every single issue that may arise.

“Every session with a particular client starts with a conversation about what is important for them because our alerts very much depend on what type of crop, region, or resources the farmer has,” Kogan explains. While some farmers want to be aware of any and every issue, others prefer not to be alerted about a select few issues because of the lack of resources they may have to tend to it.

“It’s very important for us not to bombard clients like this telling them ‘you have x, y, z issues’ if they don’t have the capabilities to fix it. So, this is why we try to be very flexible to fit their needs. However, because we make it more feasible to monitor plant growth and detect disease ahead of time, it helps the farmers reduce the use of agrochemical inputs,” states Kogan.

How Can Fermata Compete?

While Fermata certainly has its fair share of competitors, their product is extremely customizable, efficient, and simple to use, giving them an economic advantage over competitors.

“First of all, we’ve designed our AI in such a way that it’s very easy to switch from one type of crop to another and one type of task to another. Plus, we have very great quality data that makes the product really competitive. We’re not only focused on tomatoes or cannabis, or flowers; our AI can handle all of them and much more, which makes it really scalable.”

Photo courtesy of Valeria Kogan.

The second advantage relates to its easy installation process. Because Fermata does not have an installation staff, they send their products to the clients themselves with simple-to-follow installation instructions. And because Fermata has experience working with conventional greenhouses and other types of indoor farms, including vertical farms, their instructions can be molded according to the client’s particular growing space.

“Even if we have a client tomorrow in South Africa or Brazil, it’s not an issue for us. We just send our equipment with instructions, and within a couple hours, the system can be up and running,” says Kogan.

“The indoor trend is really growing,” Kogan states. “In many countries, especially in Asia, there is a lack of space for traditional agriculture, so it’s very important to use any available industrial space for efficient food production. Our technologies make indoor farms competitive,” she concludes.

This ZAVIT Article was also published in Israel21c on 28 Jul. 2021