Israeli Startup Aims to Convert Carbon Emissions Into Natural Gas

May 13, 2021A new technological prototype from a new Israeli company may make it possible to make circular use of the carbon dioxide emitted from combustion engines. Will closing the loop in this way even be feasible or economically viable?

With the planet still warming at an unprecedented rate, the countries of the world are currently in a race against time to reduce their greenhouse gas (GHG) emissions. During a recent international and virtual climate summit, attended by 40 world leaders, US President Joe Biden pledged to slash America’s GHG emissions by 50% below 2005 emissions levels by 2030. Canada, China, South Korea, Germany and France also announced similar plans and targets revolving around emission reductions, technological improvements, and transformations regarding infrastructure and economy.

Israel too has also stepped up its climate commitments and pledged similar goals regarding its own GHG emissions. In mid-April, Environmental Protection Minister Gila Gamliel announced The Climate Law, a bill that authorizes the reduction of GHG emission by at least 27% by 2030 and at least 85% by 2050 compared to 2015 emissions levels. According to the bill, priority targets include industrial energy conservation, electrifying transport, and greater waste recycling.

It’s an ambitious goal—one that will take considerable effort from Israeli companies such as Shahar Solutions, a recently established startup that is developing a prototype device capable of capturing 100% of carbon dioxide emissions from internal combustion engines before converting it into synthetic natural gas for long-term energy storage, according to its founders.

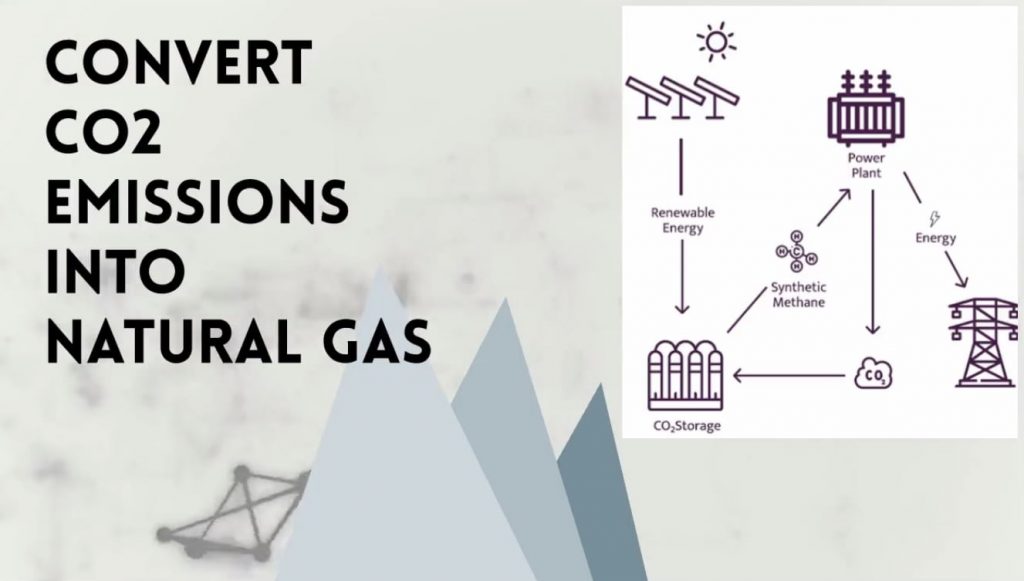

Ultimately, the goal for all combustion systems is to run on renewable electricity considering the zero carbon economies mandated by the Paris Climate Agreement by 2050. Therefore, the ability to store energy in the form of natural gas while simultaneously capturing the entirety of carbon dioxide emissions from burning that gas can theoretically create a closed loop on carbon. This means that current combustion infrastructure may still play a critical role in achieving a clean energy future.

Made Possible by the Sabatier Reaction

Founded in 2019 by electrical engineer Natan Shahar and his prior mentor Prof. Gadi Golan from Ariel University’s Department of Electrical Engineering, their innovation was inspired by Shahar’s previous engineering consultant work in New York where homeowners approached him to find a solution to reduce their greenhouse gas emissions following new regulations.

According to Shahar Solutions, the prototype, a special kind of balloon that can be sized to fit with a specific motor, collects materials emitted from combustion engines of private cars, trucks, or even a power plant. The various substances released in the combustion process such as carbon dioxide, nitrogen, and water vapor are collected inside the balloon where they undergo various chemical processes that separate the carbon dioxide from the rest of the particles. “In the end, we convert the carbon dioxide into methane,” says Golan.

The carbon dioxide-methane production technology used by the company is based on the Sabatier reaction, a scientific principle discovered as early as 1897 by Nobel Prize-winning French chemist Paul Sabatier. According to this principle, both methane and water can be produced from combining hydrogen and carbon dioxide at 400°C and applying considerable pressure in the presence of Nickel, the most widely used catalyst to accelerate the chemical reaction.

Interestingly however, outside its applications for Mars-related projects, the Sabatier reaction has not been used commercially to date because of its hydrogen requirement. Although hydrogen is the most common element in the universe, it almost exclusively exists on Earth in the form of compounds, the most prominent being water. While it is possible to extract hydrogen from water emitted from combustion engines, it requires a very large investment of energy to do so, which has deterred manufacturers from using it for economic purposes.

Closing the Loop

Shahar Solutions has come up with a number of ideas designed to address the difficulty of obtaining much of the energy needed to produce hydrogen in a cost-effective way. “One option is to use free electricity from alternative energies, such as solar cells that will be attached to our system,” says Golan. “Another option is to work with minus rates, which apply from midnight.”

In various countries around the world, electricity is cheaper during these hours, so people prefer to use electricity at times when consumption is lower, rather than during daylight hours when there is a greater load on power plants. In Israel, this tariff is applied to consumers who voluntarily choose this option for billing. According to Golan, the system they developed is capable of storing the engine emissions in the balloons and converting it to methane at a time when the energy is cheap.

It should be noted that methane itself is a greenhouse gas, whose effect is 28 times greater than that of carbon dioxide over 100-year period in the atmosphere. Therefore, the new development also includes alternative ways to use methane to avoid its release into the atmosphere.

“The methane can be stored until the next time the combustion engine is used, or returned directly to the engine and burned, which will improve engine performance,” says Golan. “Now, the burning of the newly produced methane will also create an emission of carbon dioxide, but this can also be captured and converted into methane in the same process, and so on.”

To date, the company has only developed a prototype of the product, suitable for private vehicle engines and generators. According to the company, the plan is to soon expand to more types of engines.

According to Golan, the product is of great importance even though it is intended for engines that run on polluting fossil fuels. “There are intentions to increase the use of renewable resources, but these are time consuming processes,” he says. According to him, a solution like the one Shahar offers may also fascinate fossil fuel producers given the fact that the demand for greener energy is increasing.

Time Will Tell

However, like any new development, the projections set by Shahar Solutions have to be taken with a grain of salt. The company is currently in a very preliminary stage, so there is still a need to confirm that the idea they present is both engineeringly feasible and economically viable.

“This is an idea of a circular economy: everything that is produced is converted back into raw materials,” explains Prof. David Broday of the Technion’s Department of Civil and Environmental Engineering. “However, it is difficult to understand at the present stage of the prototype how the process is carried out economically in different engines, and the devil is always in the details.”

“Carbon dioxide is a substance that is not easy to grasp, and unfortunately, 100% efficiency is a figure that only presently exists in stories,” he adds.

Another problematic issue is the use of energy in the hydrogen production process. “The amount of energy required for the process is very large, so if the system is running on renewable energy, it will need a field of solar panels, and the operation won’t be small,” says Broday. “Furthermore, if electricity from the national grid is used, it is important to remember that a significant percentage of it is produced from perishable sources (in 2020, about 94% – O.Y & M.K.Z), so it should be noted that the emission will not move from one place to another.”

There are also concerns that the new development may perpetuate the pollution emitted in the refining and transport of fossil fuels and the emissions of other combustion pollutants such as fine particulate matter (PM2.5), nitrogen and sulfur oxides, mercury vapor, and other volatile organic compounds.

In addition, there is also the possibility that the implementation of theoretically closed loop carbon dioxide combustion will prolong fossil fuel use in the future, and potentially slow the rate of transition to renewable energies.

Will Shahar Solutions’ promises come true? Time will tell. Either way, there is no doubt that in the struggle against the climate crisis there is always a crucial need to think outside the box, which may kickstart both small and possibly large steps in the right direction for the sake of the environment.

This ZAVIT Article was also published in NoCamels on 11 May 2021